Look, I’ve been in the building materials business for years and I can tell you for free that inventory management can make or break your business. Finding the right barcode scanner can boost or hinder your operation.

It’s like trying to find the perfect pair of shoes – comfort, durability, and style all matter. But in this case, we’re talking about scanning speed, accuracy, and compatibility.

Trust me, I’ve had my fair share of scanner mishaps!

Did you know that using barcode scanners can reduce inventory errors by up to 67%? That’s right, folks! I learned this gem from a Scandit report, and it blew my mind.

No more gazing at tiny labels or typos of numbers into a spreadsheet. With the right scanner, you’ll be zipping through your inventory like a hot knife through butter.

In this guide, we’ll dive deep into the world of barcode scanners.

I’ll share my hard-earned wisdom on what features to look for, review the top 7 scanners that’ll make your inventory dreams come true, and even peek into the crystal ball of barcode technology.

So, grab a cup of coffee (or tea, I don’t judge), and let’s get scanning!

What Are The Best Barcode Scanners For Building Inventory

Here are the best barcode scanners for inventory management.

1. Zebra DS3608-ER Rugged Scanner

Best for: Large warehouses, industrial environments, and businesses that need long-range scanning capabilities.

If you’re dealing with high shelves or need to scan pallets from a distance, this is your new best friend.

Okay, where do I start with this beast?

Zebra DS3608-ER is like the tank of barcode scanners. It’s tough as nails and can scan barcodes from as far as 70 feet away!

Key Features:

- Extended range scanning (up to 70 feet)

- Rugged design (survives 8-foot drops to concrete)

- Scans 1D and 2D barcodes

- Corded and cordless options are available

Pros:

- Incredibly durable (seriously, you could probably run this over with a forklift)

- Long-range scanning is a game-changer for large warehouses

- Fast and accurate, even on damaged or dirty barcodes

Cons:

- It’s on the pricier side (quality doesn’t come cheap, folks)

- Might be overkill for smaller operations

- It’s a bit bulky (but hey, you can’t have everything)

2. Honeywell Voyager 1452g Wireless Scanner

Best for: Retail environments, small to medium-sized businesses, and mobile inventory management.

If you need to move around freely while scanning and don’t need extreme durability, this scanner hits the sweet spot.

Now, if the Zebra is a tank, the Honeywell Voyager 1452g is like a sports car – sleek, fast, and perfect for zipping around a retail floor.

Key Features:

- Wireless with 30-foot range

- Scans 1D and 2D barcodes

- Field-replaceable battery

- Can scan barcodes on smartphone screens

Pros:

- Lightweight and comfortable to use all day

- Great battery life (up to 14 hours)

- Versatile – works well in retail, healthcare, and light industrial settings

Cons:

- Not as rugged as some industrial models

- Limited range compared to some other wireless models

- Charging cradle sold separately (come on, Honeywell!)

3. Symbol LS2208 Handheld Scanner

Best for: Budget-conscious businesses, startups, and small retail operations.

If you’re just getting started with inventory management and don’t need added features, this is a solid choice.

Symbol LS2208 – the Nokia 3310 of barcode scanners. It’s simple, reliable, and gets the job done without breaking the bank.

Key Features:

- Scans 1D barcodes

- Plug-and-play USB connectivity

- Durable construction (withstands 5-foot drops)

- Wide working range

Pros:

- Affordable – great for businesses on a budget

- Simple to use – even technophobes can figure it out

- Reliable – it just keeps working, day in and day out

Cons:

- Only scans 1D barcodes (no QR codes here, folks)

- Wired only – no wireless freedom

- Basic functionality might not suit complex inventory needs

4. Datalogic PowerScan PD9530 Industrial Scanner

Best for: Harsh industrial environments, cold storage facilities, and businesses that need a scanner that can take a beating.

If your work environment would make other scanners cry, this is the one for you.

Now we’re talking serious business.

Datalogic PowerScan PD9530 is like the Swiss Army knife of industrial scanners.

I’ve seen this bad boy in action in a freezing cold storage facility, and it didn’t even break a sweat (unlike me).

Key Features:

- Scans 1D and 2D barcodes

- Rugged design with IP65 sealing

- Extended range scanning

- Available in corded and cordless models

Pros:

- Extremely durable – works in dust, water, and extreme temperatures

- Powerful scanning capabilities, even on reflective surfaces

- Ergonomic design reduces user fatigue

Cons:

- High price point (but worth it for harsh environments)

- Might be too specialized for general retail use

- Heavier than some other models

5. KOAMTAC KDC470 Bluetooth Barcode Scanner

Best for: Mobile inventory management, businesses that use smartphones or tablets for tracking, and situations where hands-free operation is a must.

If you want to feel like you’re living in the future, give this a try.

Here’s a fun little gadget – KOAMTAC KDC470. It’s like having a tiny, powerful scanner right on your finger!

I used this for a pop-up inventory event once, and it felt like I was in a sci-fi movie.

Key Features:

- Ring-style scanner worn on the finger

- Bluetooth connectivity

- Scans 1D and 2D barcodes

- Compatible with iOS, Android, and Windows devices

Pros:

- Hands-free scanning is a game-changer for multitasking

- Compact and lightweight

- Great for mobile inventory with smartphones or tablets

Cons:

- Battery life isn’t as long as larger models

- May take some getting used to (I felt like a cyborg at first)

- Not as durable as some industrial scanners

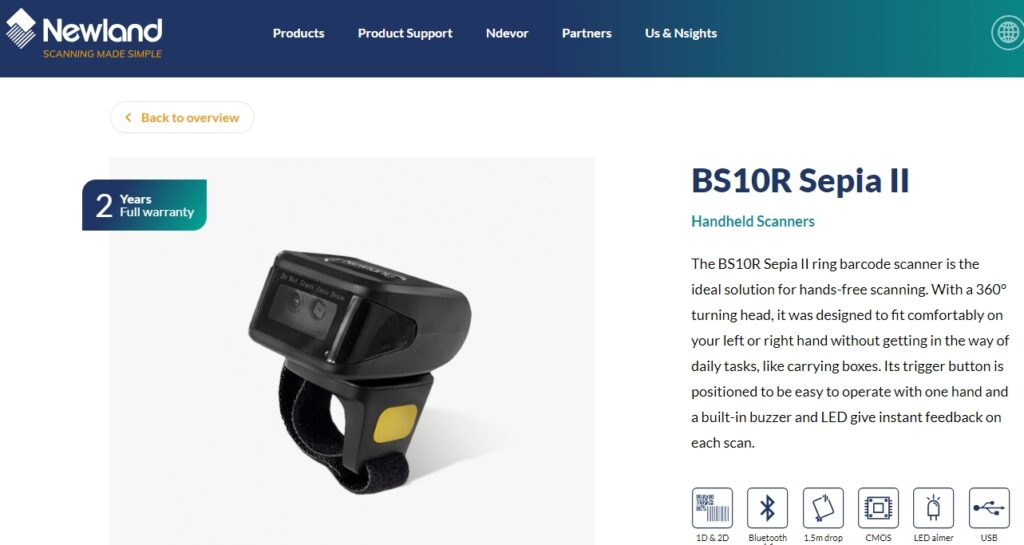

6. Newland BS10R Ringlike Bluetooth Scanner

Best for: Warehouse workers who need free hands, retail environments with high-volume scanning, and businesses looking to improve efficiency in picking and packing operations.

If multitasking is your middle name, this scanner’s got your back (or rather, your finger).

Speaking of feeling like you’re in the future, let me introduce you to the Newland BS10R.

This little ringlike scanner is another hands-free wonder that’s perfect for those of us who need to juggle multiple tasks at once.

Key Features:

- Ring-style scanner for finger wearing

- Bluetooth connectivity with 10m range

- Scans 1D and 2D barcodes

- Compatible with Android, iOS, and Windows

Pros:

- Frees up both hands for other tasks

- Lightweight and comfortable for all-day use

- Good battery life for its size (up to 12 hours)

Cons:

- Limited range compared to larger scanners

- May not be suitable for very rough environments

- Smaller screen can be harder to read for some users

7. Socket Mobile S740 Universal Barcode Scanner

Best for: Businesses that use a variety of devices for inventory management, retail environments that need flexibility, and companies looking for a scanner that can adapt to different situations.

If you want a jack-of-all-trades scanner, this is your go-to.

Last but not least, we have the Socket Mobile S740.

This scanner is like the chameleon of the barcode world – it adapts to almost any situation.

I’ve used this in a variety of settings, from a small boutique to a medium-sized warehouse, and it’s always up for the challenge.

Key Features:

- Scans 1D and 2D barcodes

- Bluetooth connectivity

- Compatible with iOS, Android, and Windows devices

- Attachable to mobile devices or used standalone

Pros:

- Extremely versatile – works with almost any device

- Good balance of durability and portability

- User-replaceable battery for extended use

Cons:

- Not as rugged as some industrial models

- Middle-of-the-road in terms of scanning range

- Software setup can be a bit tricky for some devices

Key Features Of A Barcode Scanner For Inventory Management

Alright, I outlined the features of specific scanners but Knowing which ones are important for your business is very key in selecting the right barcode scanner.

Now let’s talk about what separates the wheat from the chaff in the world of barcode scanners.

Scanning Technology

You’ve got 1D and 2D scanners. 1D is your classic barcode, while 2D handles QR codes and other fancy patterns.

If you’re just dealing with standard barcodes, 1D might be enough.

But let me tell you, having a 2D scanner will save you more than once when suppliers start using QR codes.

Durability

Listen, accidents happen. Imagine a scanner dropping from a 10-foot ladder (don’t ask), just know that most scanners won’t survive the fall.

Look for rugged scanners if you’re working in tough environments.

Connectivity

USB, Bluetooth, Wi-Fi – oh my! Think about how you’ll be using the scanner.

If you’re always on the move, wireless is the way to go.

But if you’re chained to a desk (my condolences), a wired USB scanner might do the trick.

Battery Life

There’s nothing worse than a scanner dying mid-inventory. Been there, done that, got the t-shirt.

Look for long battery life or hot-swappable batteries if you’re doing marathon scanning sessions.

Software Compatibility

Make sure your scanner plays nice with your inventory management software.

I once bought a fancy scanner only to find out it was about as compatible with our software as oil and water.

Not fun.

Ergonomics

You’ll be holding this thing for hours. Make sure it feels good in your hand.

Your wrists will thank you later.

Price

Look, we all love a good deal. But remember, sometimes you get what you pay for.

Balance your budget with your needs.

How To Integrate Barcode Scanners Into Your Inventory System

Alright, now that we’ve covered the crème de la crème of barcode scanners, let’s talk about getting these bad boys up and running.

Trust me, I’ve been through the integration process more times than I care to count, and I’ve got some tips to make your life easier.

Choose The Right Software:

Your scanner is only as good as the software it’s paired with.

Make sure your inventory management software is compatible with your chosen scanner.

I once spent a whole weekend trying to get a scanner to work with our old software – don’t be like me, check compatibility first!

Set Up And Configure:

Most modern scanners are pretty plug-and-play, but you might need to install drivers or software.

Follow the manufacturer’s instructions carefully. And for the love of all that is holy, don’t lose that instruction manual!

Train Your Staff:

Even the fanciest scanner is useless if your team doesn’t know how to use it.

Set up a training session and be patient – there’s always a learning curve.

We got there in the end!

Establish Best Practices:

Create a set of guidelines for scanner use and maintenance.

This includes things like proper handling, cleaning procedures, and what to do if there’s a problem.

An ounce of prevention is worth a pound of cure, folks.

Regular Maintenance:

Keep your scanners clean and charged.

A dirty scanner is an inaccurate scanner, and nobody wants that.

I once found a scanner that hadn’t been cleaned in months – it was like an archaeological dig!

Troubleshooting:

Know the basics of troubleshooting your scanners.

Common issues include connectivity problems, battery issues, and software glitches.

Having a go-to troubleshooting guide can save you a lot of headaches.

Stay Updated:

Keep your scanner’s firmware and your inventory software up to date.

Updates often include important fixes and improvements.

Remember, integrating new technology is always a bit of a learning process.

Be patient, stay positive, and don’t be afraid to reach out to the manufacturer’s support team if you hit a snag.

We’ve all been there!

Future Trends In Barcode Scanning Technology

Hold onto your hats, folks, because the world of barcode scanning is evolving faster than a TikTok dance moves!

Let’s take a peek into the crystal ball and see what the future holds.

Image-Based Scanning:

Say goodbye to those red laser lines! Image-based scanners are becoming more common, using cameras to capture and process barcodes.

They’re faster, more accurate, and can handle damaged or poorly printed barcodes like a champ.

Augmented Reality (Ar) Integration:

Imagine pointing your scanner at a shelf and seeing real-time inventory data floating in the air.

AR-enabled scanners are making this sci-fi dream a reality.

I saw a demo of this at a trade show last year, and let me tell you, it was like something out of Iron Man!

AI and Machine Learning:

Smart scanners are getting, well, smarter!

AI-powered scanners can learn to recognize products, predict inventory needs, and even detect counterfeit goods.

It’s like having a tiny robot brain in your scanner – scary and awesome at the same time.

RFID and NFC Technologies:

While not strictly barcode tech, RFID (Radio-Frequency Identification) and NFC (Near Field Communication) are changing the game for inventory management.

Imagine scanning an entire pallet of goods in seconds, or tapping your phone to get a product’s entire history.

The future is now, people!

Cloud Integration:

More scanners are connecting directly to the cloud, allowing for real-time inventory updates across multiple locations.

No more end-of-day syncing headaches!

I remember the days of manually inputting data from each store location – trust me, cloud integration is a godsend.

Environmental Sustainability:

As we all become more eco-conscious, scanner manufacturers are following suit.

Expect to see more scanners made from recycled materials, with longer lifespans and energy-efficient designs.

Mother Earth will thank us!

Wearable Technology:

We touched on ring scanners earlier, but this is just the beginning.

From smart glasses that can scan barcodes to wrist-mounted devices, wearable scanning tech is going to revolutionize how we interact with inventory.

I can’t wait to feel like a cyborg warehouse worker of the future!

The world of barcode scanning is evolving at lightning speed, and it’s an exciting time to be in inventory management.

Who knows? In a few years, we might be scanning products with our minds!

Okay, maybe that’s a bit far-fetched, but a guy can dream, right?

Conclusion

From rugged industrial scanners to futuristic wearable tech, the world of barcode scanners is a lot more exciting than most people give it credit for.

Trust me, I’ve seen eyes glaze over at parties when I start talking about scan rates and durability ratings, but hey, to each their own!

Choosing the right barcode scanner for your inventory management needs is crucial.

It’s not just about picking the fanciest or most expensive option out there.

It’s about finding the perfect fit for your specific business needs, budget, and environment.

Remember, the best scanner is the one that makes your life easier and your inventory management more efficient.

Maybe it’s the rugged Zebra DS3608-ER for your sprawling warehouse, or perhaps the nimble KOAMTAC KDC470 for your boutique retail store.

Heck, it might even be the trusty old Symbol LS2208 if you’re just starting out.

As you make your decision, think about your daily operations. Will you be scanning from a distance or up close?

Do you need something that can withstand drops and spills? How important is mobility?

Answer these questions, and you’ll be well on your way to scanner nirvana.

And don’t forget, technology is always evolving. What seems cutting-edge today might be old news tomorrow.

Stay informed about the latest trends and be ready to adapt.

Your future self will thank you when you’re effortlessly managing inventory like a pro!

Now, I’d love to hear from you!

Have you had any hilarious (or horrifying) experiences with barcode scanners?

Any favorite models I didn’t mention? Drop a comment below and let’s geek out about inventory management together.

After all, misery loves company, and so does efficiency!

FAQs On Barcode Scanners

Q. What’s the difference between 1D and 2D barcode scanners?

A. 1D scanners read the traditional barcodes – you know, the ones that look like a bunch of vertical lines.

These are great for simple product identification and are still widely used in retail and grocery stores.

2D scanners, on the other hand, can read those fancy QR codes and Data Matrix codes.

These bad boys can store way more information in a smaller space.

If you’re just dealing with standard barcodes, a 1D scanner might be enough.

But if you want to future-proof your operation or need to scan more complex codes, go for a 2D scanner.

Trust me, you’ll thank me later when you don’t have to upgrade in a year!

Q. Can I use my smartphone as a barcode scanner for inventory management?

A. Okay, the million-dollar question! The short answer is yes, you can.

There are plenty of apps out there that turn your smartphone into a barcode scanner.

I’ve used them in a pinch, and they can be pretty handy for small operations or occasional use.

But here’s the thing – while your smartphone can do the job, it’s not always the most efficient solution for large-scale inventory management.

Dedicated scanners are faster, more accurate, and often more durable.

Plus, they’re designed specifically for the task, so they’re more comfortable to use for long periods.

That said, if you’re a small business owner just starting out, or if you need a backup solution, a smartphone app can be a great way to dip your toes into the world of barcode scanning without breaking the bank.

Q. How do wireless barcode scanners compare to wired ones in terms of reliability?

A. Oh, the great wired vs. wireless debate!

I’ve had my fair share of arguments about this over the years.

Wired scanners have the advantage of a constant power supply and a stable connection.

They’re like the faithful old dog that’s always by your side. You don’t have to worry about battery life or signal interference.

Wireless scanners, on the other hand, offer freedom of movement and can be more convenient in many situations.

They’re like the energetic puppy that runs circles around the old dog.

In terms of reliability, modern wireless scanners have come a long way.

With advancements in battery life and wireless technology, they’re now nearly as reliable as their wired counterparts.

The choice really depends on your specific needs…

If you’re always on the move, go wireless. If you’re stationed at a fixed point, wired might be the way to go.

And if you can’t decide, some models offer both options!

Q. What maintenance is required for barcode scanners?

A. Ah, maintenance – the unsung hero of scanner longevity!

Thought I could just use a scanner non-stop without any TLC.

Spoiler alert: I was wrong. Here’s the good news: most barcode scanners are pretty low-maintenance.

But a little care goes a long way:

- Keep it clean: Use a soft, dry cloth to wipe down the scanner regularly. For the scanning window, use a lint-free cloth or pre-moistened lens wipe. No harsh chemicals, please!

- Check the cables: If you’re using a wired scanner, inspect the cables periodically for wear and tear.

- Battery care: For wireless models, follow the manufacturer’s guidelines for battery care. This usually means fully charging and discharging the battery periodically.

- Software updates: Keep your scanner’s firmware up to date. These updates often include performance improvements and bug fixes.

- Environmental control: Try to keep your scanner away from extreme temperatures, dust, and moisture.

Remember, a well-maintained scanner is a happy scanner. And a happy scanner means a happy inventory manager!

Q. Are there any industry-specific barcode scanners I should consider?

A. Absolutely! Just like you wouldn’t wear flip-flops to a black-tie event (or maybe you would, I don’t judge), different industries often require specialized scanning solutions.

For healthcare, there are scanners designed to withstand frequent disinfection and that can read the tiny barcodes on medication packaging.

In manufacturing and warehousing, you might need scanners with long-range capabilities or that can withstand harsh environments.

I’m talking about scanners that can survive drops, dust, and extreme temperatures.

Retail often requires scanners that can read barcodes off of smartphone screens for things like digital coupons or loyalty cards.

I remember the first time a customer tried to get me to scan a coupon off their phone with an old laser scanner – talk about a comedy of errors!

And let’s not forget about outdoor use cases like inventory management for things like shipping containers.

There are scanners designed to work in bright sunlight and all weather conditions.

It’s like sunscreen for your scanner, but way more high-tech.

The key is to think about your specific use case and environment.

Don’t be afraid to reach out to scanner manufacturers or vendors – they often have industry-specific expertise and can guide you to the right solution.

Remember, choosing the right barcode scanner is all about understanding your needs and finding the tool that best fits those needs.

It’s like finding the sweet spot – not too hot, not too cold, but just right!